Smart Vision

Intelligent computer vision system For smart factory, smart farm and smart citythrough OpenCV and Deep Learning technique in

low cost embedded device.

Smart Vision which was developed by OPENSYSNET’s own technology is intelligent computer vision solution

that can be applied various industry such as smart factory, smart farm, smart city.

Smart Vision is an intelligent solution that can be work quickly and accurately instead of human.

It can be used in various fields like defect detection, component alignment as a part of smart factory.

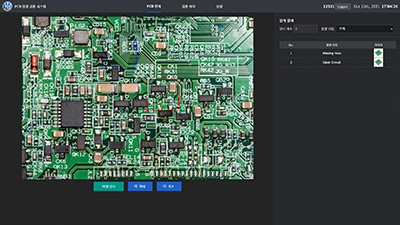

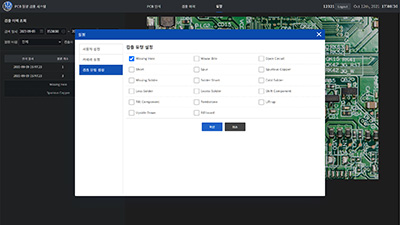

Defect Detection Vision Solution is a solution that can improves the quality of manufacturing process and

productivity by determining defected product and minimizing defect rate though vision monitoring in the factory manufacturing line

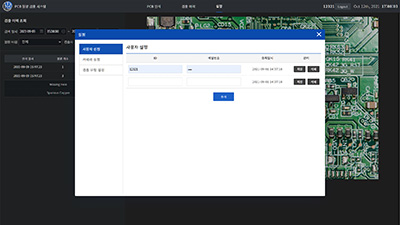

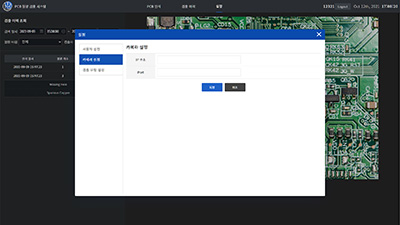

Our solution has been verified its performance in PCB defect detection system which can detect open circuit,

checking component position, detecting soldering on PCB

Our vision solution can be applied in various industries such as containers manufacturing, inspection packing status, inspection product appearance, etc.

And customer can experience decreasing defect rate and cost cutting for dealing with claim through our high performance AI solution

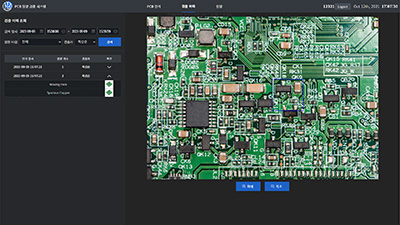

OPENSYSNET Vision S/W is performing for detecting parts and calculating angle according to

the pre-defined shape to interworking with alignment robot in factory automation

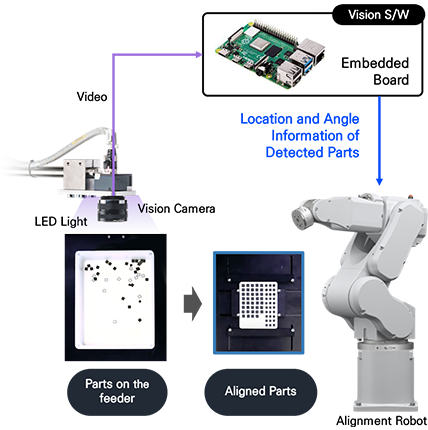

Our Smart Vision Solution is collaborating with SCARA robot for harvesting tomato, pepper, strawberry as smart farm 4.0 project.

Smart vision box can train and detect any kind of crops based on Baseline Learning and Transfer Learning of deep learning detection model.

OPENSYSNET Smart Vision Box is edge type AI vision box which perform object detection and recognition rapidly

based on LiDAR camera and Deep learning object detection model.

Smart Vison Box (Front)

Smart Vison Box (Front)

Smart Vison Box (Back)

Smart Vison Box (Back)

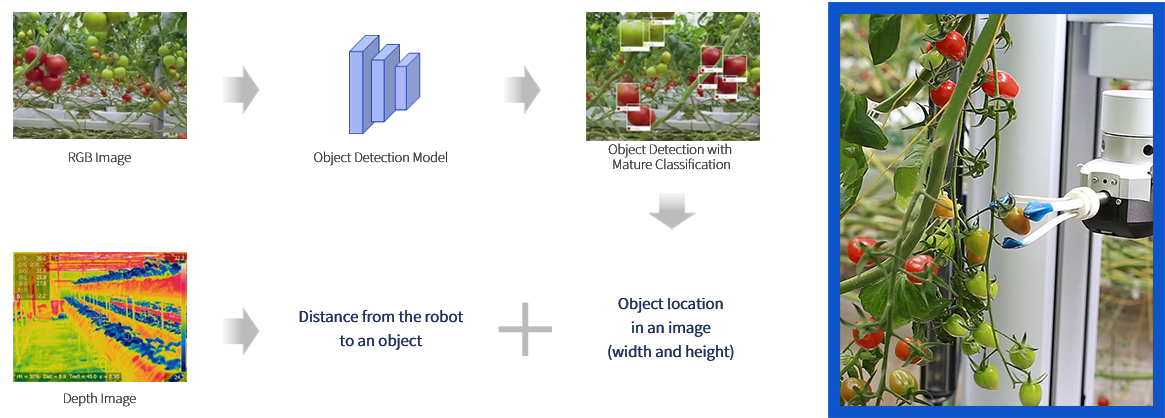

| Item | Specification |

|---|---|

| CPU | Quad-core ARM Cortex-A57 MPCore processor |

| GPU | NVIDIA Maxwell architecture with 128 NVIDIA CUDA® cores |

| Memory | 4 GB 64-bit LPDDR4, 1600MHz 25.6 GB/s |

| Storage | 16 GB eMMC 5.1 |

| Video Encode | 250MP/sec |

| Video Decode | 500MP/sec |

| Boot Source | eMMC / USB |

| Networking | Gigabit Ethernet, M.2 Key E |

| Peripheral Interface | 4x USB 3.0, USB 2.0 Micro-B |

| HDMI 2.0 and eDP 1.4 | |

| GPIO, I2C, I2S, SPI, UART | |

| LiDAR Camera | Ideal Range : 0.25m ~ 9m |

| FOV : 70º * 43º | |

| Accuracy : 5mm ~ 14mm | |

| Frame Rate : 30fps |

Our software can be performing various type of object detection and recognition based on AI deep learning training.

HIGH PERFORMANCE

HIGH PERFORMANCE

High-Accuracy & High-Speed Detection

INTER OPERABILITY

INTER OPERABILITY

Working with Various Robot & Camera

COST EFFICENCY

COST EFFICENCY

Low Cost for Installing S/W with Camera

SUPPORT MULTI-PLATFORM

SUPPORT MULTI-PLATFORM

Support various platforms such as CPU, GPU and TPU

Machin Vision Solution based on deep learning supports intelligent vision service that provide human’s vision and judgment ability .

Please feel free to contact us if there is any questions.

We will get back to you soon.